Purpose of the Document

To present a detailed technical summary of Vortex Process Technology (VPT) and explain how vortex-induced physical changes to water enhance performance in cooling, ice-making, and industrial water treatment—without chemicals or energy input.

What is VPT?

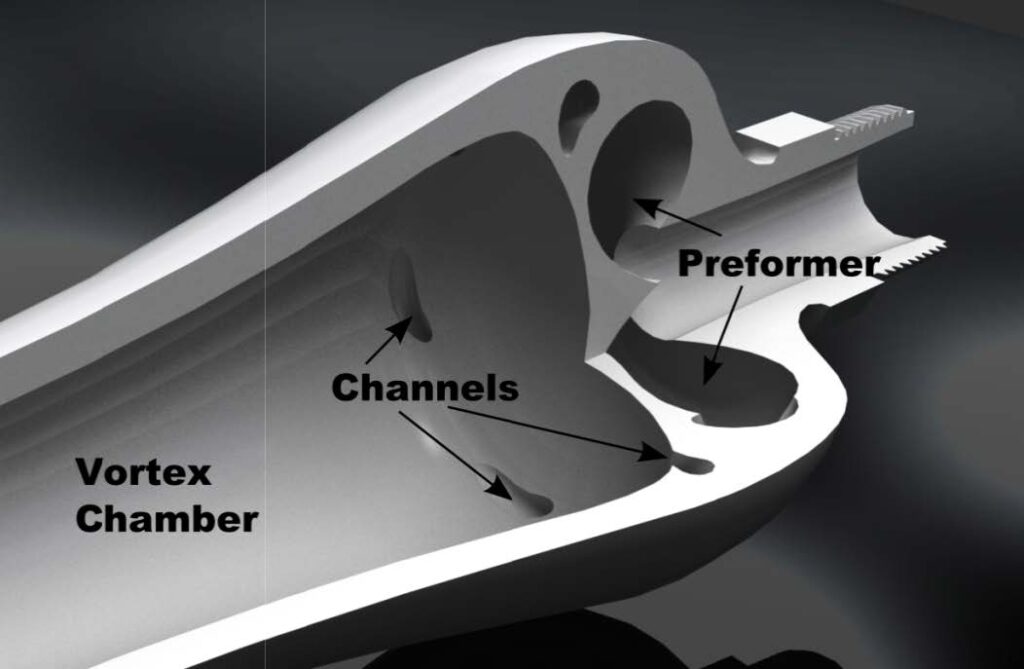

VPT is an inline, energy-free water treatment system that uses fluid dynamics and biomimicry to improve the physical properties of water by:

- Creating a high-speed vortex flow

- Inducing cavitation and degassing

- Causing crystallization of minerals like calcium

- Structurally transforming water to improve heat transfer

Scientific Effects on Water Properties

| Property | Change through VPT |

|---|---|

| Viscosity | ↓ Up to 17% — allows faster flow & better transfer |

| Conductivity | ↑ ~3% — indicates restructured molecular alignment |

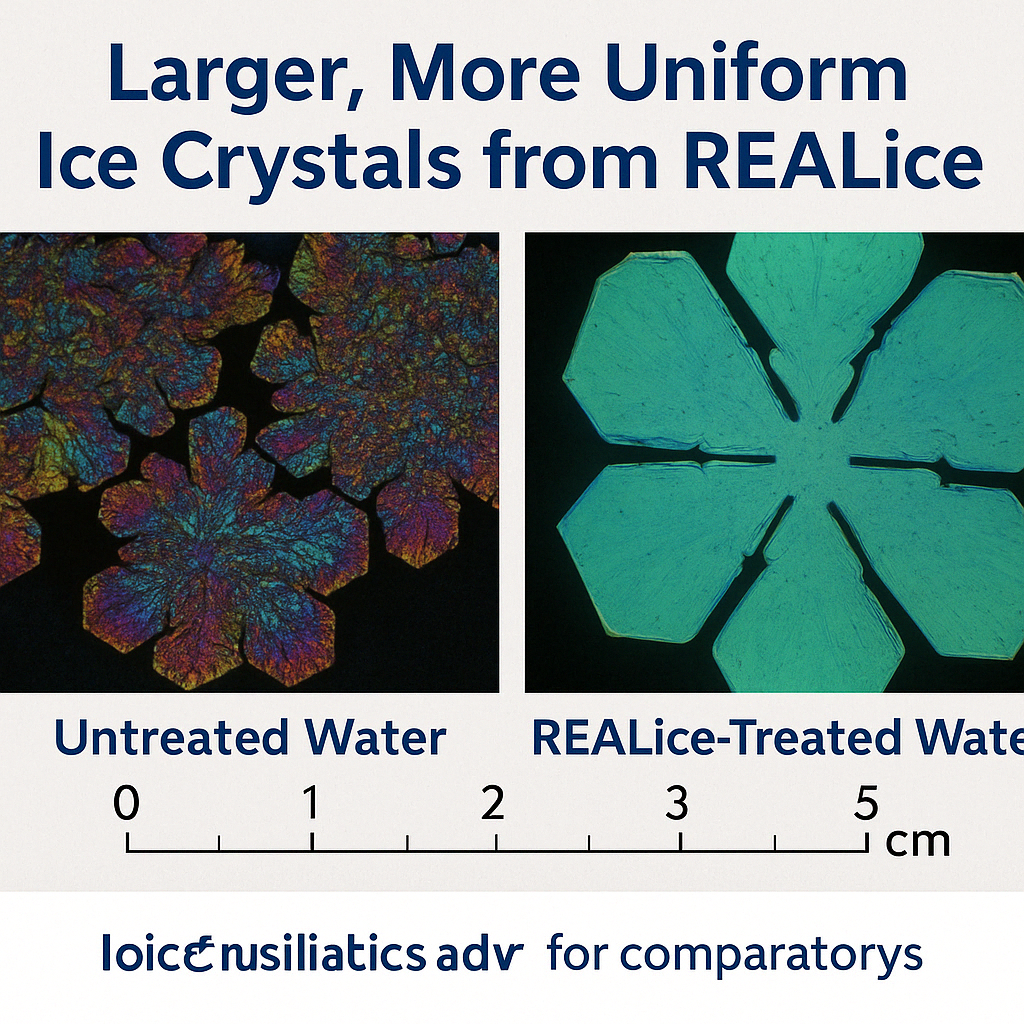

| Microbubbles | Removed — better freezing, reduced foaming |

| Mineral Crystallization | Formation of non-scaling aragonite & calcite |

| Surface Tension | ↓ Enhances spreading and thermal efficiency |

Applications & Benefits

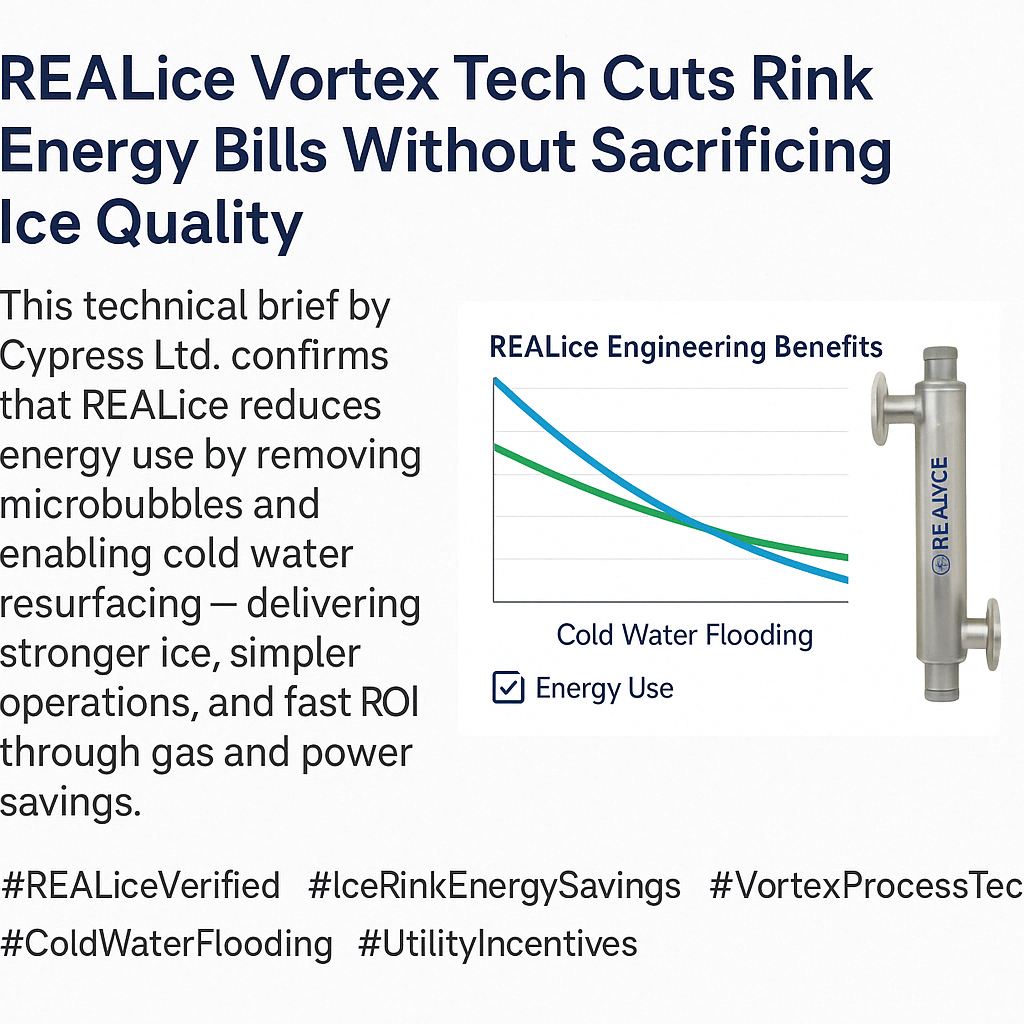

Ice Production (REALice):

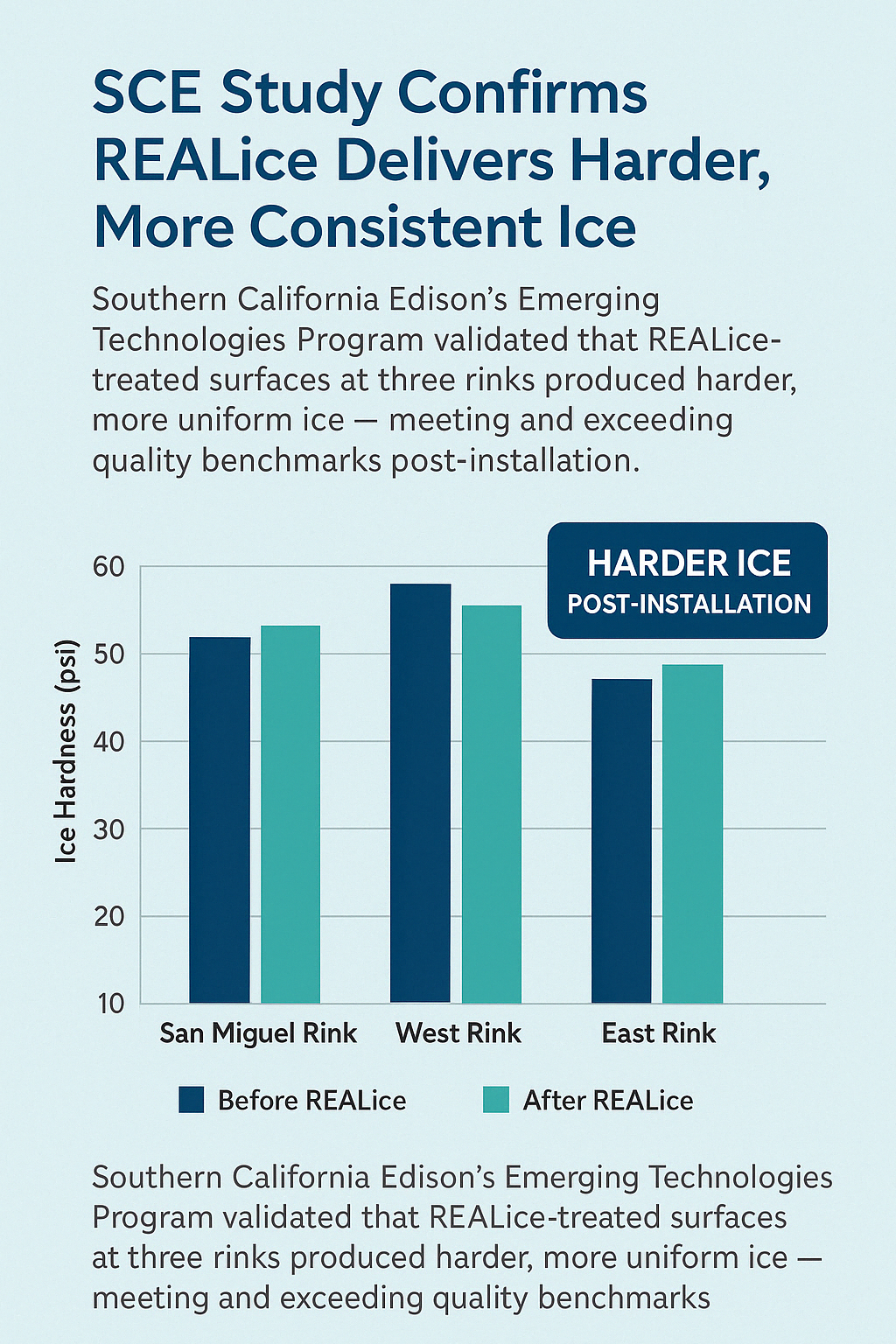

- Harder, clearer ice

- Reduced ice melt and gouging

- No hot water needed for resurfacing

Cooling Towers:

- Improved heat exchanger efficiency

- Reduced scaling and biofouling

- Increased cycles of concentration

Industrial Water Treatment:

- Chemical-free and energy-free

- Prevents mineral buildup

- Enhances system lifespan and lowers OPEX

Validated By

- Eindhoven University of Technology

- SLU Sweden (Swedish University of Agricultural Sciences)

- Independent labs using conductivity, heat transfer, and crystallography testing

Conclusion

VPT is a proven, scalable, and sustainable water treatment method delivering:

- Lower energy use

- Zero chemicals

- Lower maintenance

- SBroad compatibility across sectors (sports, industrial, HVAC, agriculture)tronger ice & better thermal exchange

This technology supports the shift to circular water systems, energy efficiency, and low-carbon operations.