Purpose of the Study

To evaluate the energy, emissions, and performance impacts of using REALice vortex-treated water for ice rink resurfacing, replacing conventional hot water with cold, degassed water in real-world Canadian arena conditions.

Technology Overview – REALice® System

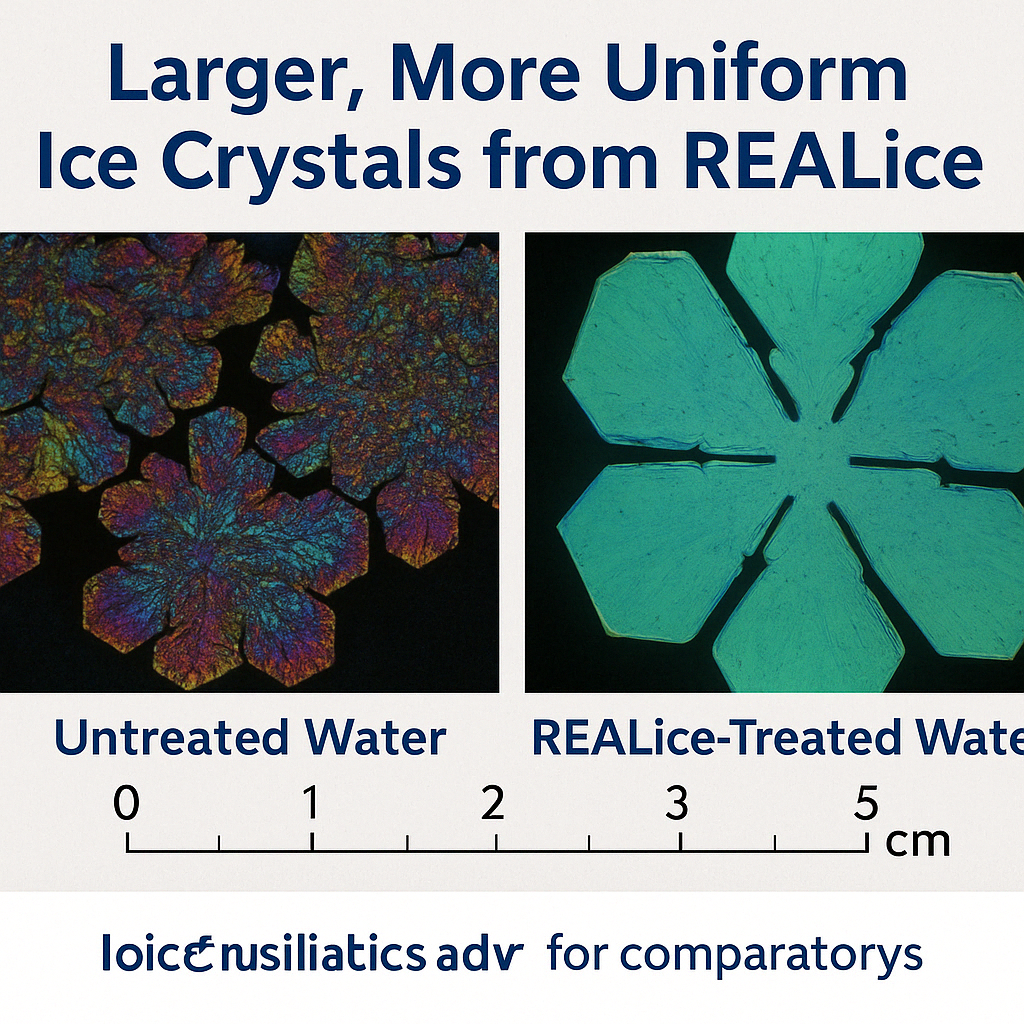

- Uses mechanical vortex treatment to remove microbubbles and entrained gases.

- Eliminates the need to heat water to 140°F (60°C) before resurfacing.

- Produces clearer, harder, more durable ice with less melting and shaving.

- Installed as plug-and-play inline retrofit to arena resurfacing systems.

Study Scope

- 10 indoor rinks across British Columbia participated.

- Ice resurfacing water temperature reduced to ~60°F (15.5°C).

- Monitored over 5–7 months for:

- Natural gas use

- Electricity for refrigeration

- Indoor ice quality

- User and operator feedback

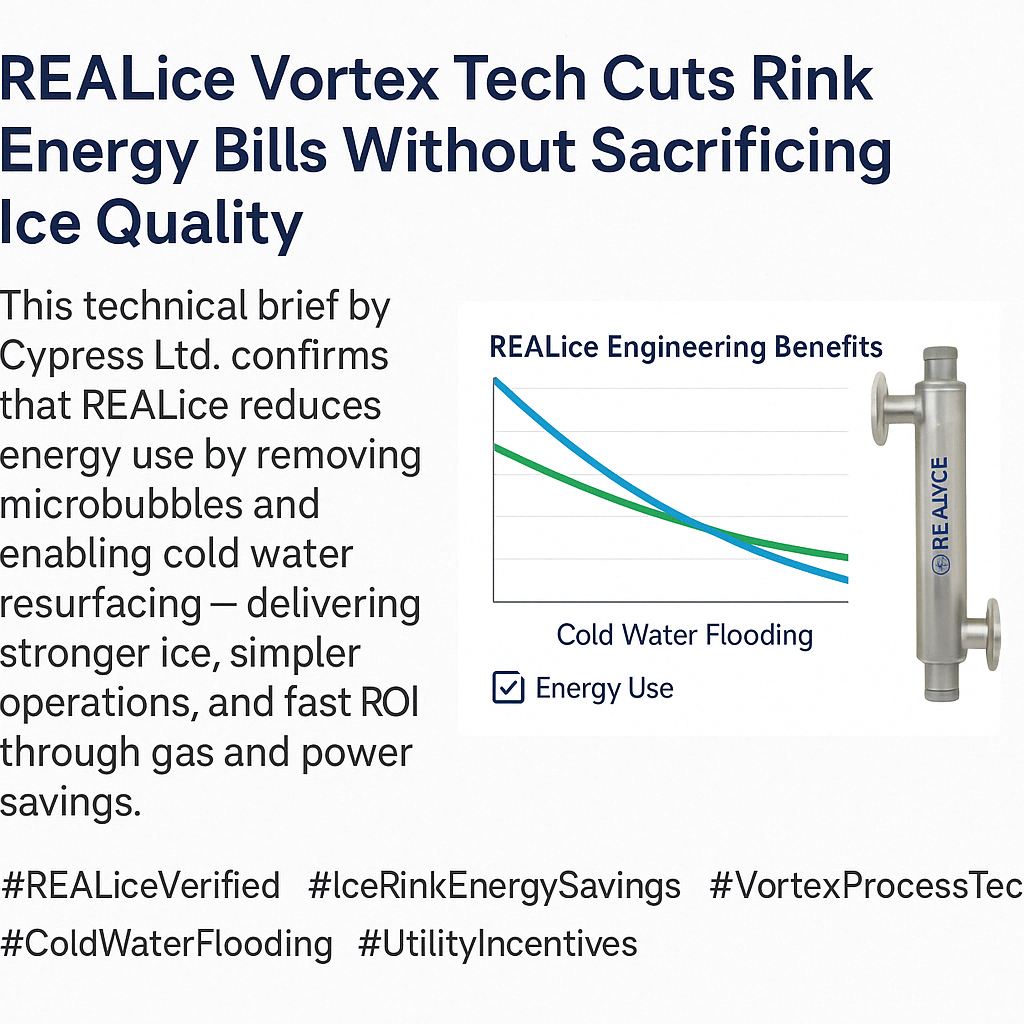

Key Results

| Impact Area | Result |

|---|---|

| Natural Gas Savings | Average: 79% reduction (heating resurfacing water) |

| Refrigeration Energy | Average: 29% reduction |

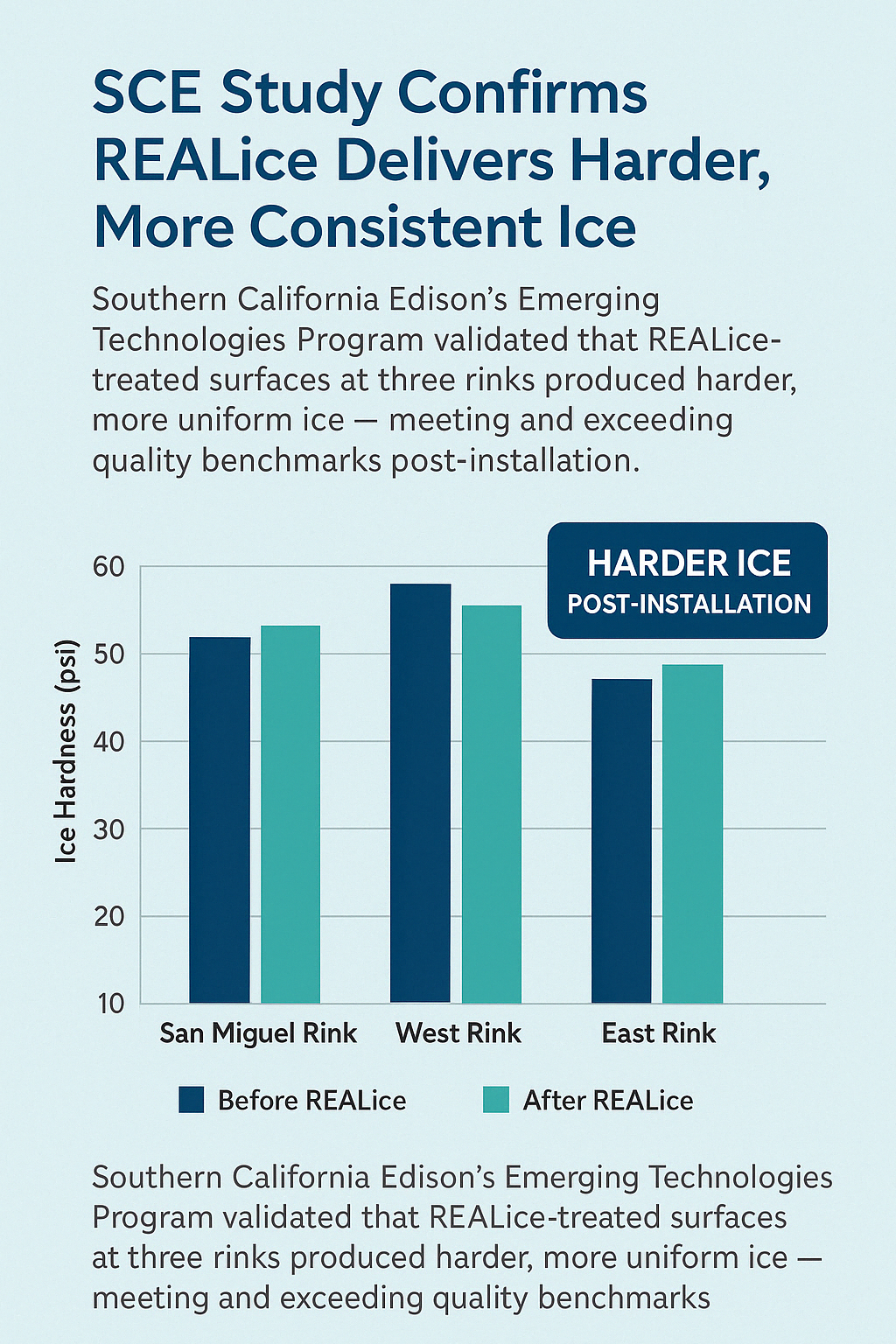

| Ice Quality | Maintained or improved, less snow, faster freeze |

| Emissions Reduction | Significant GHG reductions across all test sites |

| Ease of Use | Positive staff feedback, minimal disruption |

| Cost Savings | ~$3,000–$9,000 CAD/year per rink (energy alone) |

Feedback & Observations

- Operators reported no negative effects on ice quality.

- Players and coaches observed fewer ruts, less snow, and smoother glide.

- Water heaters remained off for months in some rinks.

Limitations & Considerations

- Refrigeration energy savings vary based on arena efficiency and climate.

- Training staff to adjust resurfacing practices is important.

- Additional ice maintenance practices (like shaving) may need review.

Conclusion

REALice® technology delivers:

- Proven energy savings in real-world arena settings

- Better environmental outcomes (GHG, water heating, refrigerants)

- Operational simplicity for municipal and private rinks

- Faster return on investment (ROI in 1–2 years)

Highly recommended for large-scale adoption across arenas and eligible for FortisBC incentives.