Objective

To evaluate the energy-saving potential and ice quality impact of the REALice vortex water treatment system at a regional Swiss ice rink under real-world operational conditions.

Technology Description – REALice®

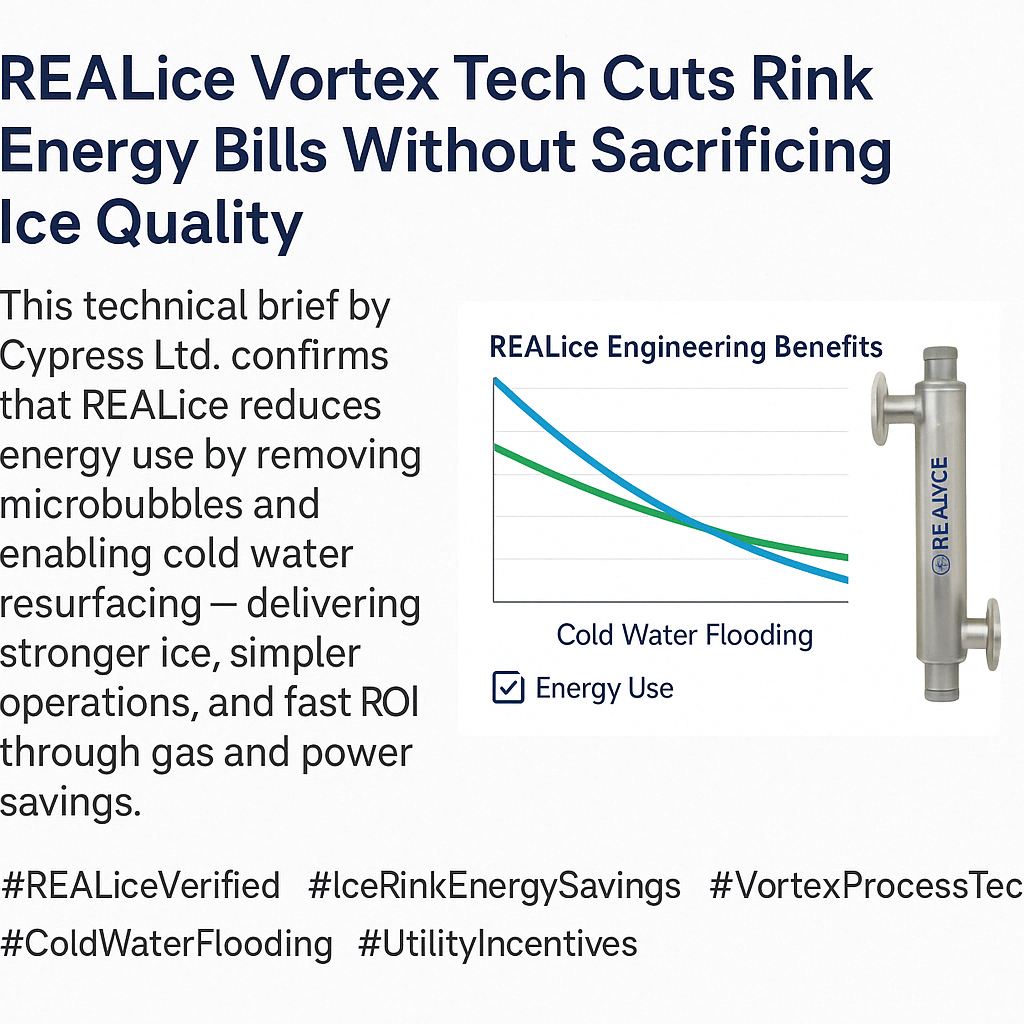

- Uses vortex motion to remove microbubbles and degas water without chemicals or energy input.

- Allows rinks to resurface using cold water (~15°C / 59°F) instead of traditional hot water (~60°C / 140°F).

- Results in faster freezing, denser ice, and reduced maintenance needs.

Test Location & Scope

- Location: KEBO Oerlikon, Zurich – Hall 2

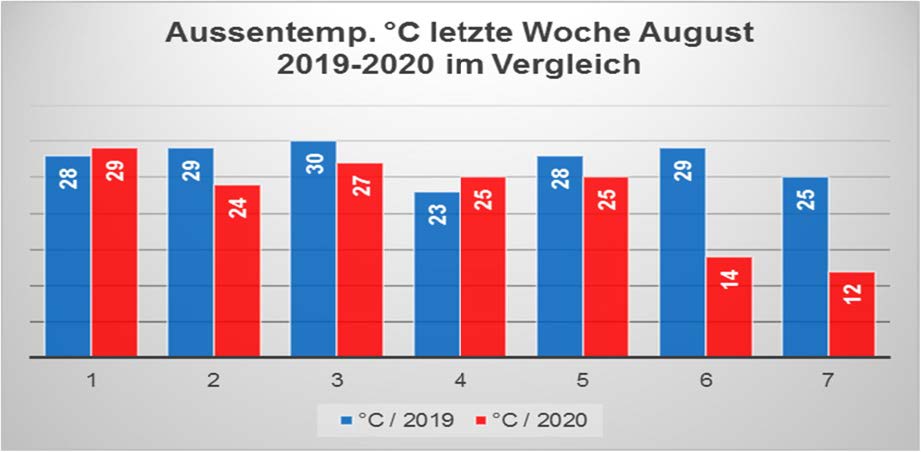

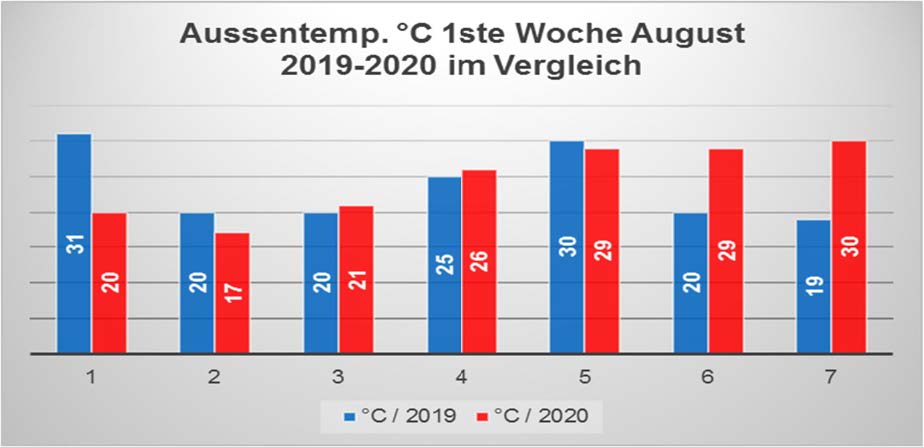

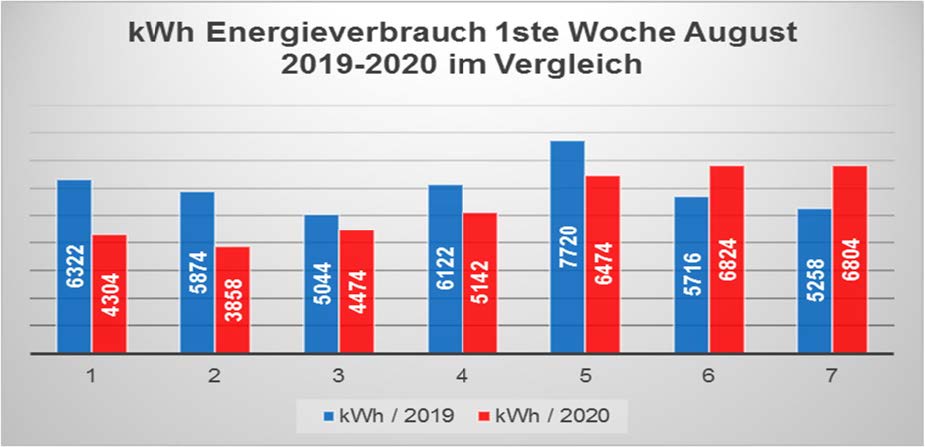

- Timeframe: August 2019 vs. August 2020 (controlled comparative weeks)

- Parameters measured:

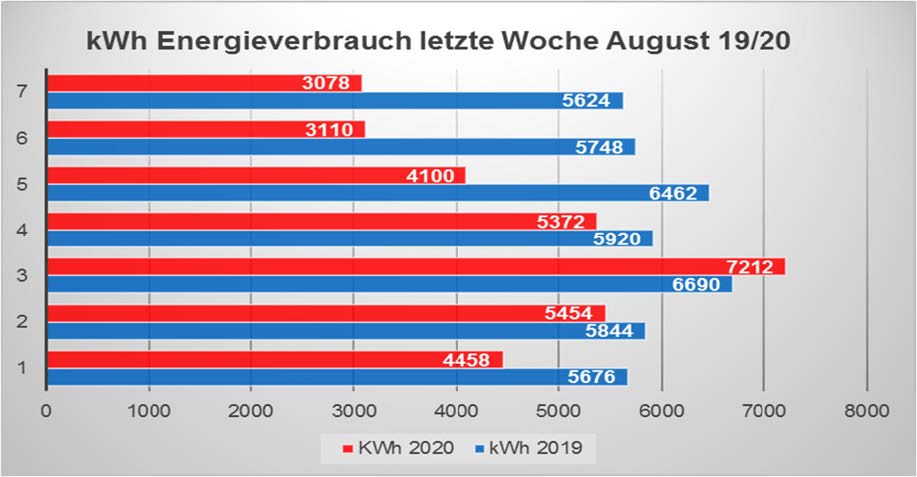

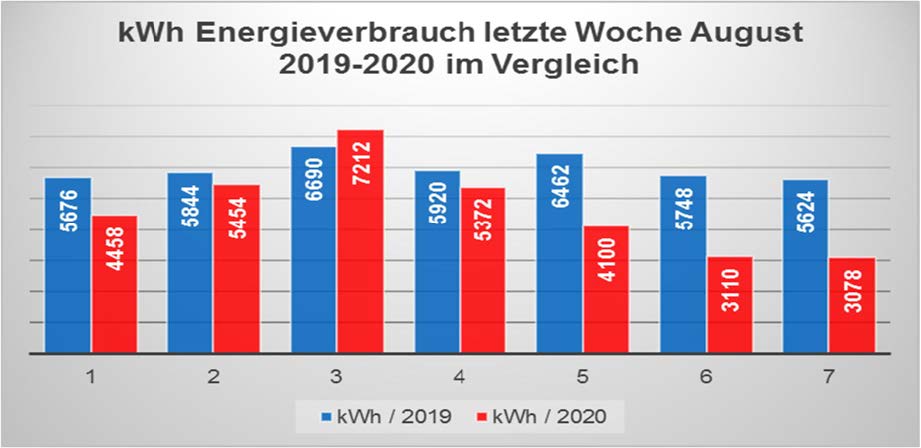

- Energy consumption (kWh)

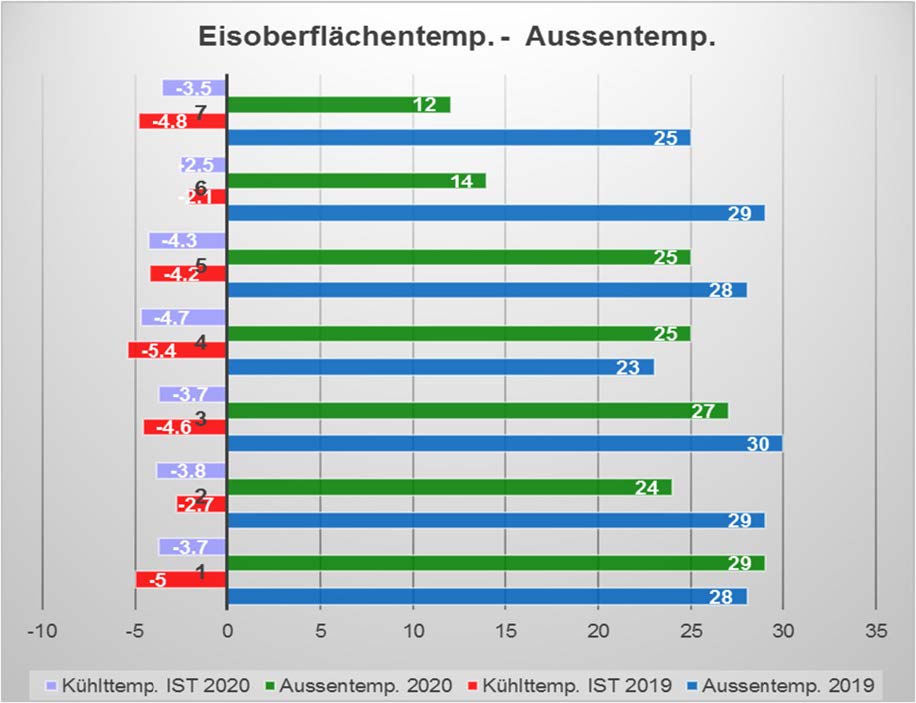

- Ice and outdoor temperatures

- Ice quality and maintenance effort

Key Findings

| Aspect | Observed Result with REALice |

|---|---|

| Energy Savings | Up to 52% lower energy use during resurfacing on hot days |

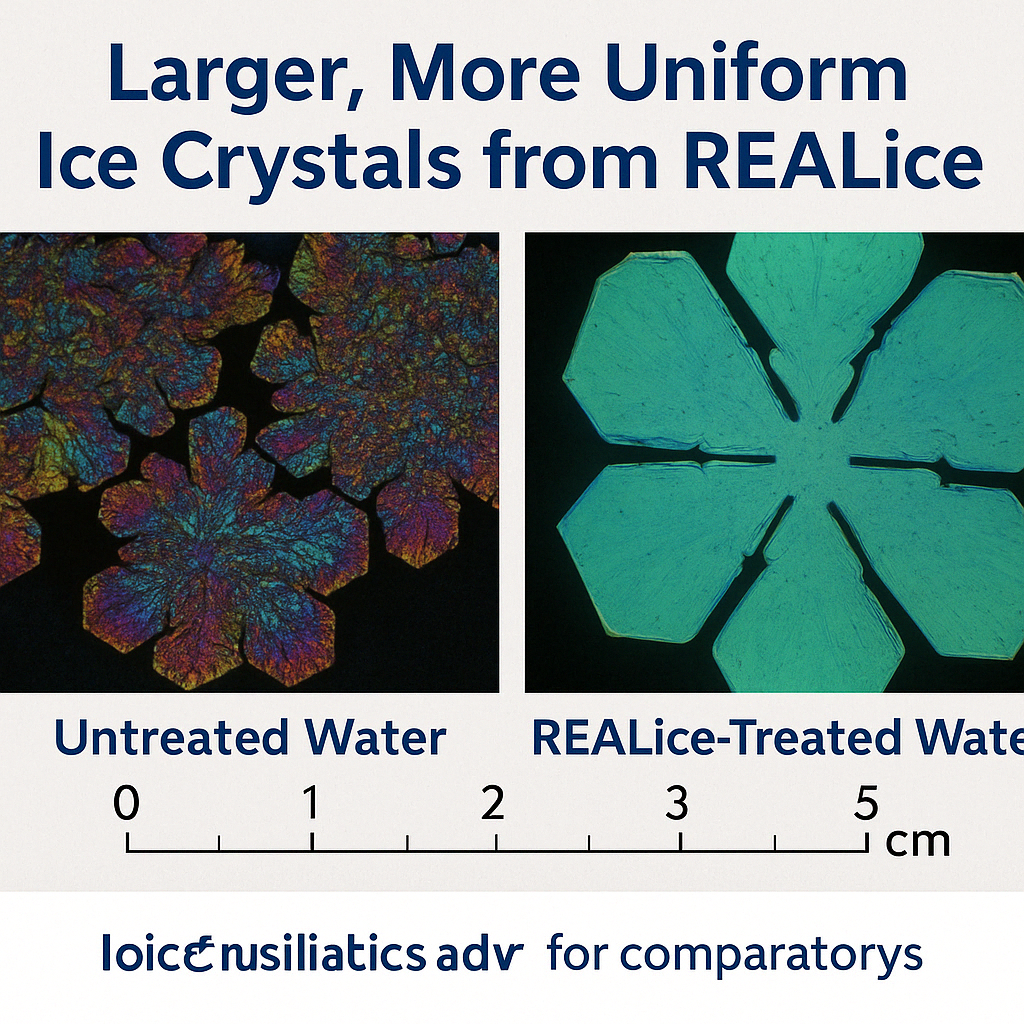

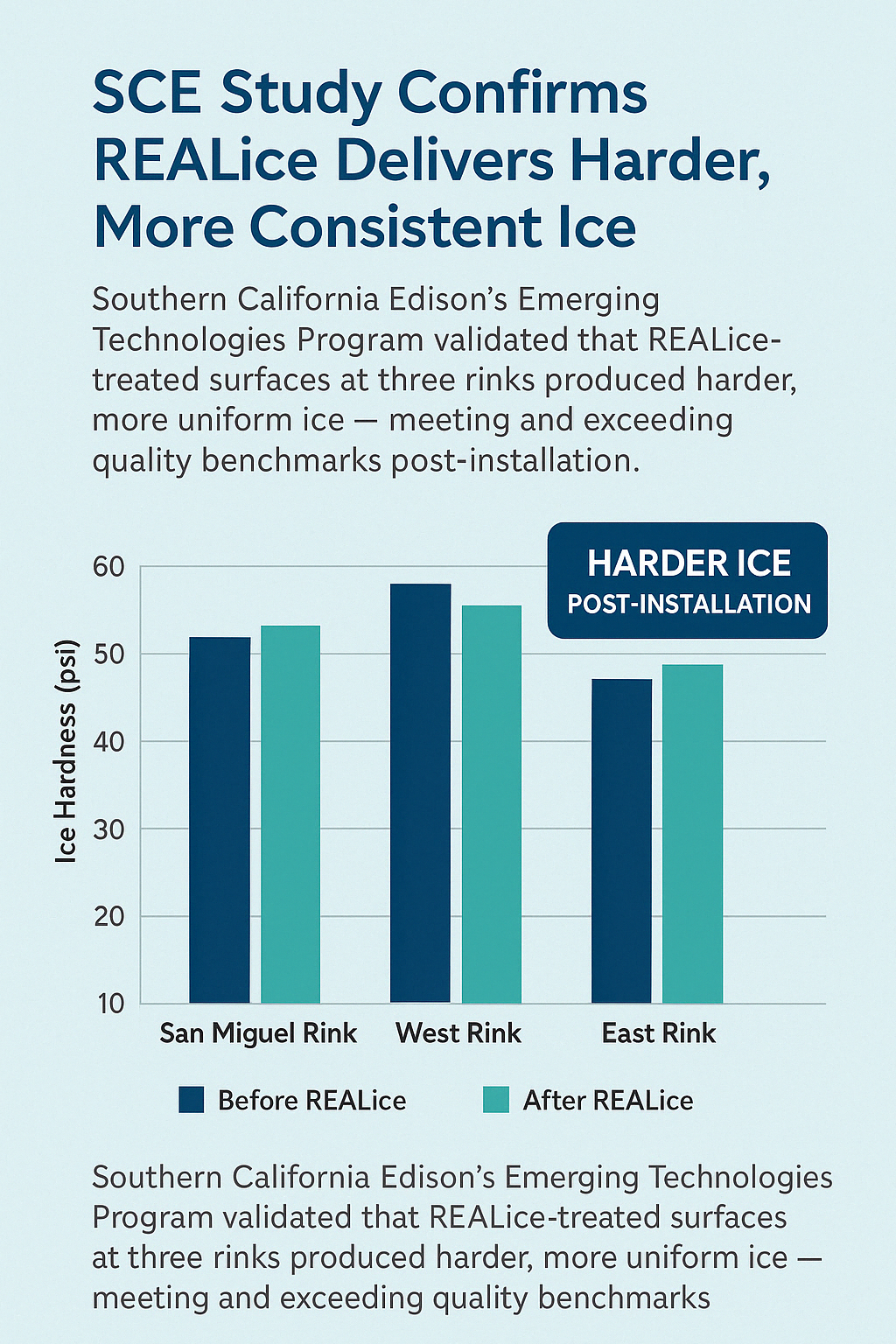

| Qualité de la glace | Harder, denser ice, fewer gouges and blowouts |

| Ice Maintenance | Faster freezing, less snow buildup, compact shavings |

| Temperature Stability | Maintained consistent ice temperatures (−3.5°C to −3.8°C) |

| Operator Feedback | Universally positive across 5+ veteran ice techs |

Feedback from Ice Technicians

- No spider cracks on base layers

- Ice is more compact, with better skate performance

- Denser ice shavings allow larger machines to clean more per round

- Fewer deep cuts, especially from figure skaters

- Ice temperatures required less adjustment, reducing refrigeration stress

Conclusions

- REALice enables significant operational energy savings, particularly during hot weather.

- Ice quality is consistently improved, even with reduced ice thickness.

- The system supports lower maintenance, better ice performance, and GHG reduction.

- Recommended for continued use and deeper integration in municipal or competitive rinks.