Acknowledgements

Southern California Edison’s Design & Engineering Services (DES) group is responsible for this project. It was developed as part of Southern California Edison’s Emerging Technology program under internal project number ET09SCE0070. DES’ Charles Kim conducted this technology evaluation with overall guidance and management from Paul Delaney.

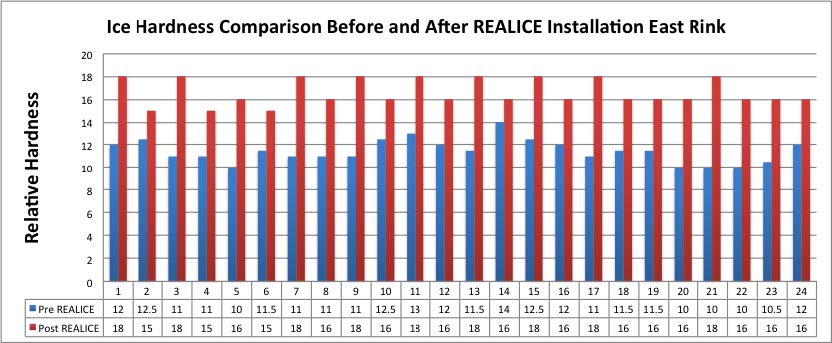

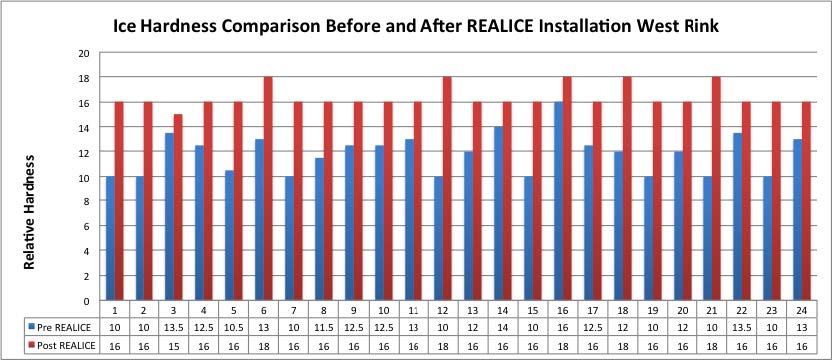

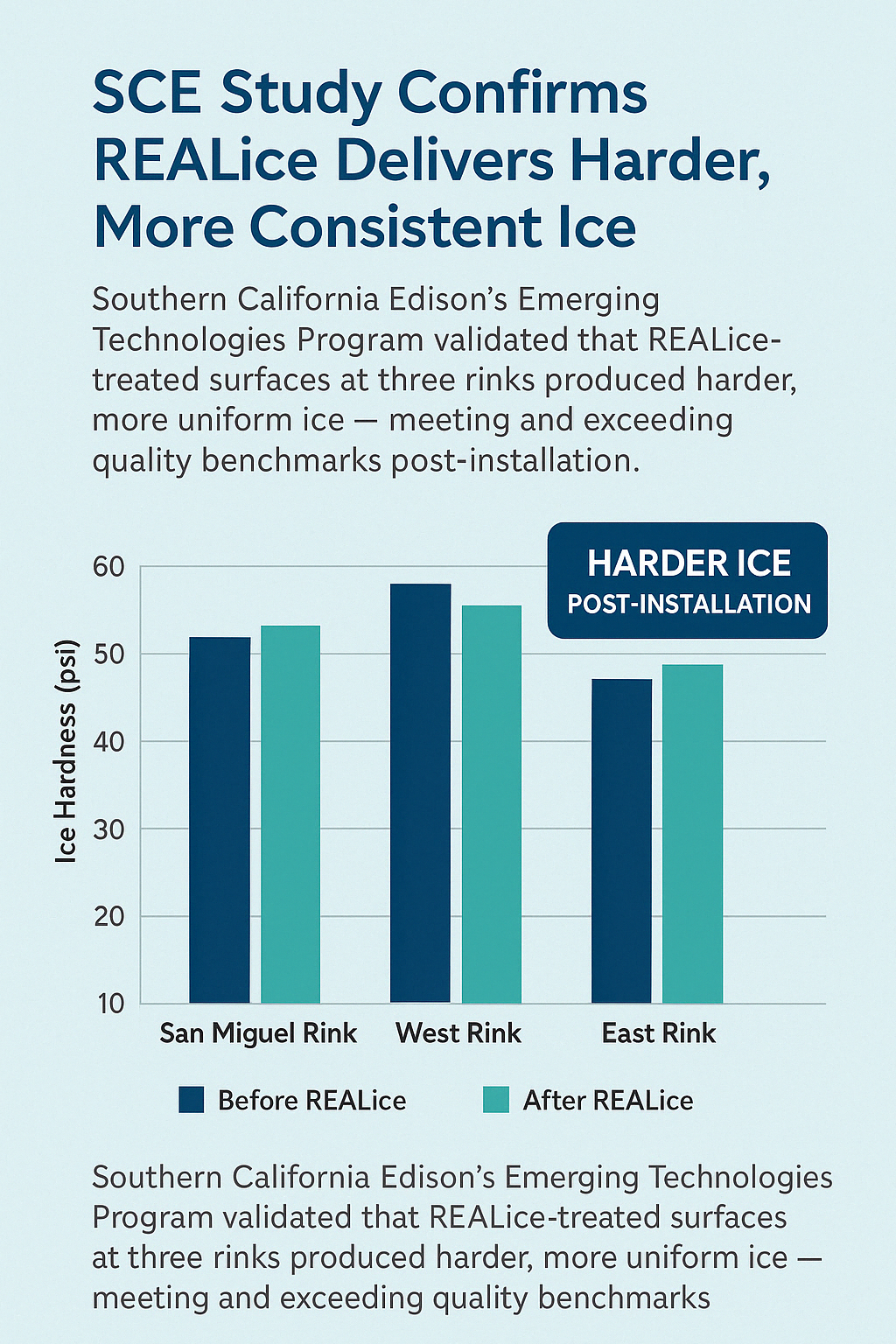

ICE QUALITY TESTING

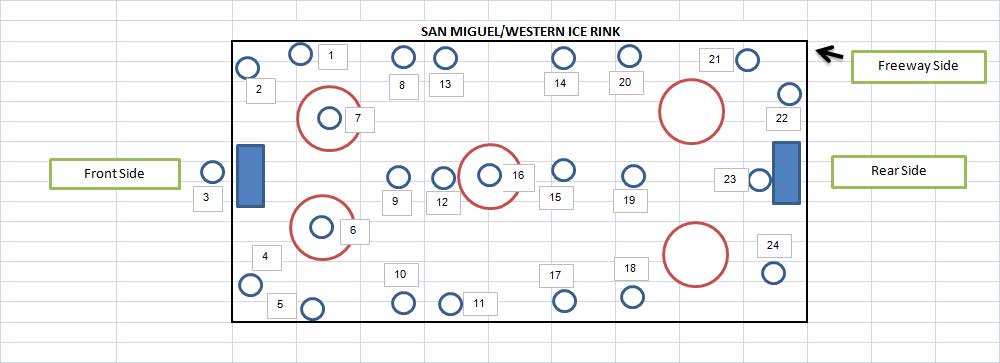

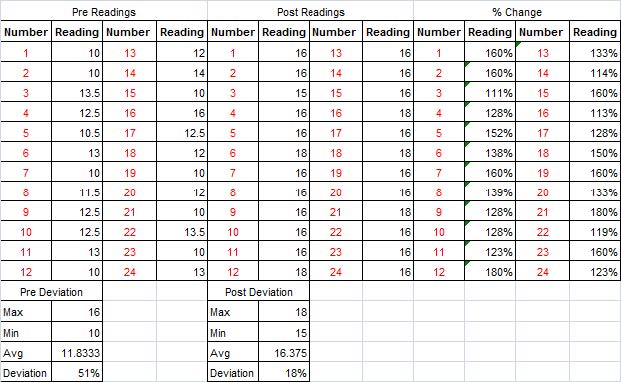

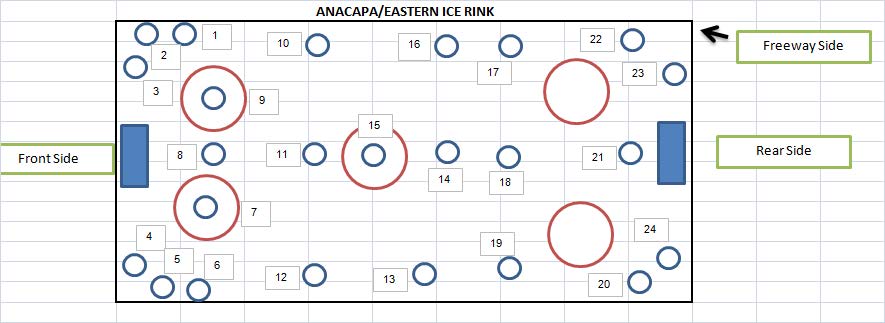

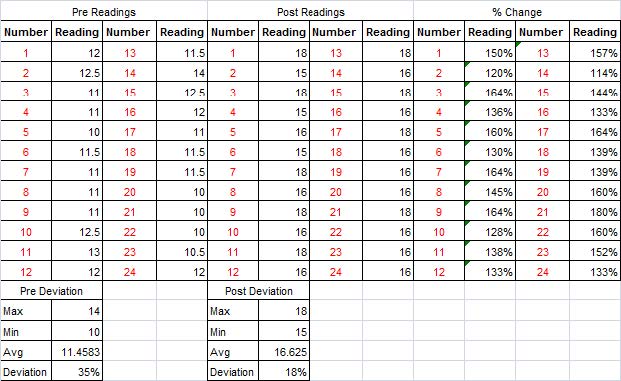

The permise of the evaluating is that the ice would be of equal or better quality upon installation of the Realice system. The ice quality of pre condition is measured by testing surface strenght of contact using a Schmidt Hammer. While this device is not designed to measure the lower surface strenght of ice accurately, this device does allow a comparative test between pre and post conditions. Figure 7 and 8 illustrate the ice quality testing results in terms of ice surface strenghts.

Specific items of note for this assessment are:

- A reading on the Schmidt Hammer® corresponds to an approximate strength of 1500 psi. It does not provide a relationship curve below a reading of 20 and below. This is the main reason that the test should only be used on a comparative basis.

- The conclusion is that the rebound numbers are as good or better after the installation of the Realice system, which meets the intent of the M & V process.

For Weest Rink the ice was on average 39% harder post installation of Realice with high of 80% and low of 11%.

For East Rink the ice was on average 46% harder post installation of Realice with a high of 80% and low of 14%. - The overall uniformity of ice strength is much better after the installation of the Realice system. This means that the ice was more consistent in hardness across the entire rink after installation.